Part of dosing technologies for Engine and Equipment Manufacturers

When approached by a leading international automotive company for a custom dosing product, Deltron worked its magic!

Dosing technologies are critical in enabling certain elements reduction capabilities of the selective catalytic reduction system. Deltron is proud to be part of such dosing solutions that suit a variety of customer applications and functions as airless or air-assisted systems.

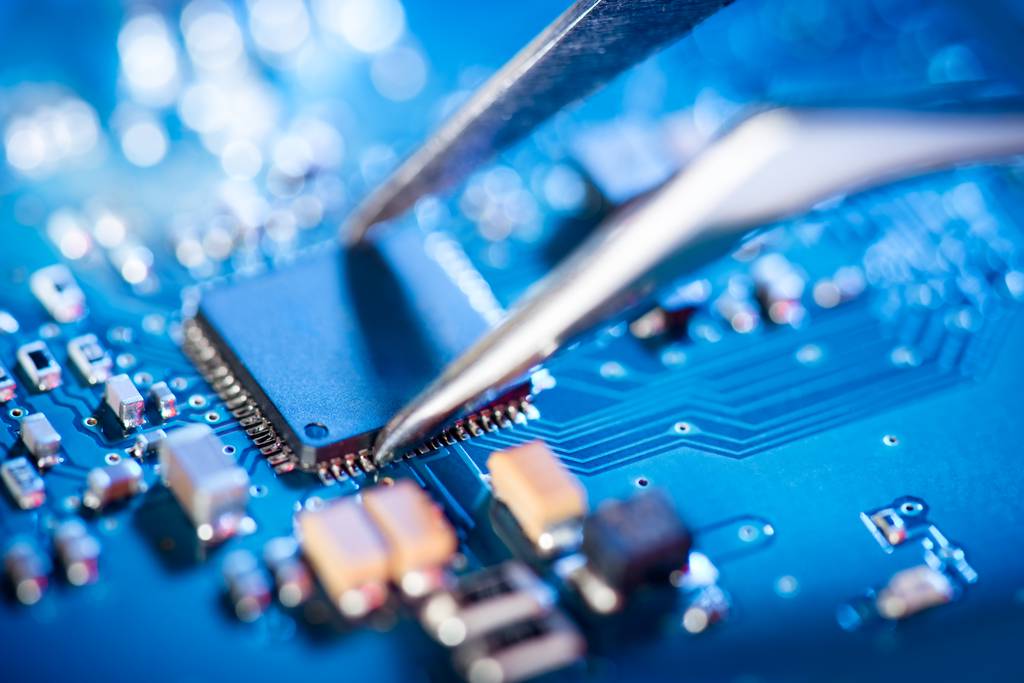

Here too, make in India for the world; the challenge was in sync with India’s vision to become one of the leaders in Electronic Manufacturing Services. This fast turnaround project required our PCB and Harness assembly expertise and the provision of e-mech parts from a specialist partner.

With over 40 years of experience in the industry, Deltron had the capabilities, supplier relationships and skills needed to reduce standard lead times. All assemblies were manufactured by our skilled technicians who worked for the highest industry standards whilst drawing together all elements of supply delivery, and exceeded the customer’s expectations.

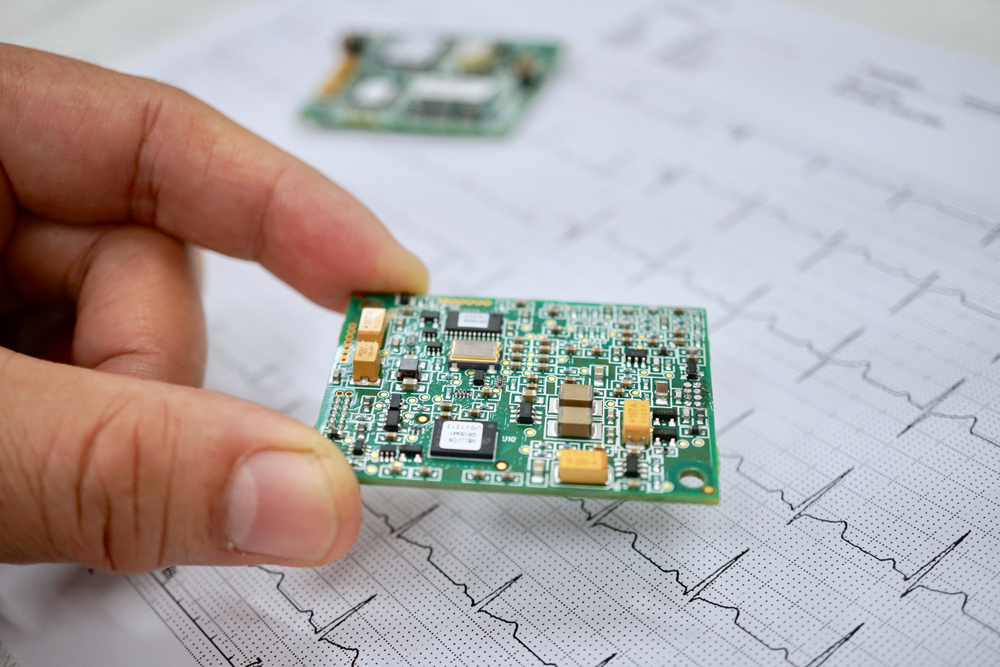

The standard lead time for a project of this complexity and size is very high. The prototype lot followed by the pilot and pre-production runs was executed in a much advanced timescale; an extremely fast timeline for a project of this size.

We honestly believe that Deltron, with all the skills under one roof and of sufficient scale, could turn this project around within the timescale. This resulted in customer confirming long term schedules with target volume running in millions.

When speed is required with a quality assembly project; or have gotten stuck waiting due to supply issues, let us know your requirements. Our electronic experts can help turn your project into a reality. Whatever your PCB assembly, cable assembly, electronics box build or overmoulding needs; we offer sound project support to our customers.

Ready to Transform Your Automotive Solutions?

Partner with Us for Automotive Innovation

Contact us to discuss your project requirements and discover how Deltron can help you achieve your goals.