PCB Assembly OR Prototyping, PCB Assembly and New Product Introduction(NPI)

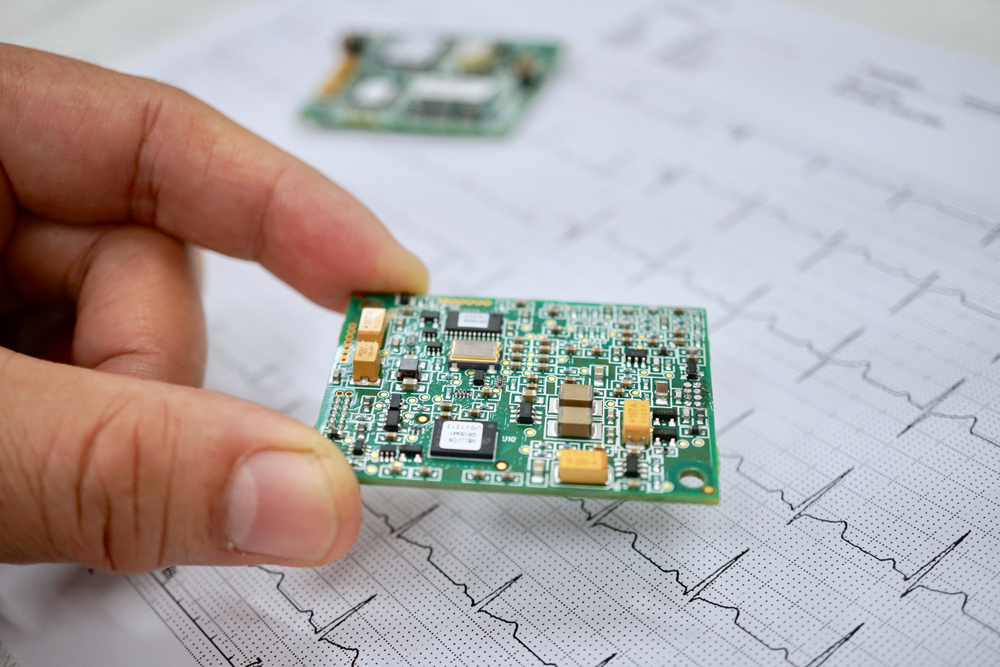

We offer printed circuit board (PCB) assembly services, starting from prototyping, new product launches to regular production ramp ups, out of different production sites. Our facilities have several SMT lines. We produce boards in varied sizes using various types of substrate boards.

Turning Concepts into Reality

PCB Assembly

Comprehensive PCB Assembly Services for Diverse Needs

From basic assemblies to complicated PCB capabilities such as flexible circuits, thermal substrates and PCBs with blind and buried vias, we are confident we can meet all your production needs through our broad range of printed circuit board assembly services.

With a long run in the electronics manufacturing service, we strongly believe that prototyping is the first step in a long-term, trustworthy partnership. Our comprehension of the challenges associated with prototyping enhances our ability to offer our customers a multitude of benefits with the necessary testing scope that enable the physical realization of the concept in a short amount of time.

Superior Component Sourcing and Advanced Assembly Capabilities

We use only the best components sources for the job, sourced from our extensive network of well-known supply chain partners.

Our facilities are also equipped with the latest machines, and our services encompass both surface-mount and through-hole assemblies. This means we can offer different levels of service — from supplying PCB assembly prototypes right through to the manufacture of complex, multi-technology printed circuit board assemblies with high-speed processes.

Additionally, our clients benefit from specialized NPI services that guarantee smooth project management. Our innovative cross-functional team model guarantees a seamless launch of the product and transition to mass production while guaranteeing that the product satisfies all demands for quality, productivity, yield, as well as those related to sourcing, supply chains, packaging, reliability, and end-user requirements.

Trusted by Industry Leaders

What Our Clients Say

Thanks to Deltron for their valuable support as our key Strategic Partner.

Ready to Transform Your Product Idea? Let’s Make It Happen

Explore Our EMS Solutions and Collaborate for Success

Contact us to discuss your project requirements and discover how Deltron can help you achieve your goals.